이미지 확대보기

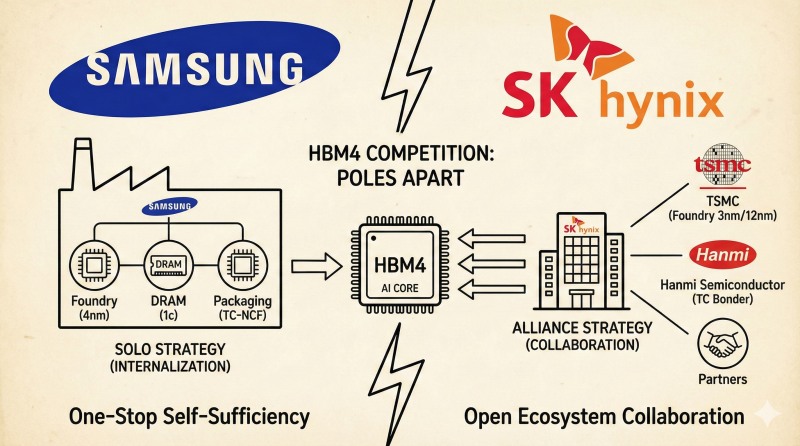

이미지 확대보기From base die to back-end processes, Samsung Electronics plans to secure technological superiority through an internalization strategy encompassing foundry and equipment. In contrast, SK Hynix is leveraging an open collaboration model that mobilizes the entire external ecosystem including TSMC and Hanmi Semiconductor, leading with verified quality and speed.

Individual DRAM chips that make up HBM are called 'core dies.' The chip located at the bottom layer is specifically designated as the 'base die (logic die).' The base die performs the critical role of directly connecting to the GPU, interpreting signals, and delivering commands to upper core dies.

Until HBM3E (5th generation), memory companies produced base dies using their own DRAM processes, but from HBM4 (6th generation), foundry (contract manufacturing) methods utilizing cutting-edge fine processes are being introduced to improve speed and power efficiency.

SK Hynix is entrusting HBM4 base die production to Taiwan's TSMC. This is because the company judged that process optimization collaboration with TSMC is essential to meet performance requirements demanded by customers. SK Hynix is known to plan to utilize TSMC's 3-nanometer (nm) and 12nm processes. Standard products for servers will be manufactured with 12nm, while customized products such as Nvidia premium GPUs and Google's custom chips (TPU) are expected to be produced with 3nm processes.

In contrast, Samsung Electronics produces HBM4 base dies using its own foundry 4nm process. Although negotiations with customers over price and volume are variables, if Samsung Electronics secures prices similar to SK Hynix, it can create a relatively higher profit structure through internalization.

Samsung Electronics, a latecomer in HBM, has a strategy of securing customers by leveraging technological capabilities. Samsung Electronics applies the 1c (6th generation) process to HBM4 DRAM.

The HBM4 performance disclosed by the two companies in October also shows differences.

Samsung Electronics specifically presented data transfer (I/O) speed and bandwidth at maximum 11Gbps and 2.8TB per second, respectively. SK Hynix only disclosed minimum levels as 'above 10Gbps' and 'above 2.6TB.' This means that even the minimum standards meet Nvidia's enhanced performance requirements.

An industry official said, "For Samsung Electronics, securing yield is key," adding, "As a leading HBM company, SK Hynix's intention to prioritize stable supply is evident."

Packaging (back-end process) strategies also differ significantly between the two companies. The core back-end process in HBM is a type of bonding process that connects stacked DRAMs. From HBM4 20-stack and above, hybrid bonding is required for yield stabilization, but previous generations are likely to maintain existing technologies.

SK Hynix uses the 'MR-MUF process' that fills the space between chips with liquid protective material after soldering. The TC (thermal compression) bonder equipment that temporarily fixes chips to substrates and chips to chips just before this process is supplied by Hanmi Semiconductor, Hanwha Semitech, and others. Since even slight misalignment causes defects, TC bonders for HBM4 are known as expensive equipment costing approximately KRW 4 billion per unit.

If SK Hynix can be likened to 'applying wood glue,' Samsung Electronics can be compared to 'attaching double-sided tape.' This is the 'TC-NCF' method that inserts film-type protective material between layers and proceeds with thermal compression. Samsung Electronics mainly receives TC bonder supplies from its subsidiary SEMES.

Gwak Horyung (horr@fntimes.com)

[관련기사]

- Samsung Electronics and SK Hynix Eye KRW 150 Trillion Operating Profit Era

- Samsung Electronics’ Jun Young-hyun Bets on HBM4 — Decision Expected in Q1 Next Year

- Samsung Foundry Seeks Rebound with ‘Made in America’ Drive

- SK Hynix Surges to 41% Operating Margin in Q2; Puts Full Force Behind HBM4 Pricing Defense

가장 핫한 경제 소식! 한국금융신문의 ‘추천뉴스’를 받아보세요~

데일리 금융경제뉴스 Copyright ⓒ 한국금융신문 & FNTIMES.com

저작권법에 의거 상업적 목적의 무단 전재, 복사, 배포 금지

!['From Heavy Industry to Humanoids' — Doosan Robotics Charts a New Future in Physical AI [K-Humanoid Wars, Part 3]](https://cfnimage.commutil.kr/phpwas/restmb_setimgmake.php?pp=006&w=284&h=214&m=5&simg=2026030310061306979141825007d12411124362.jpg&nmt=18)

!['Samsung's Bet on the Future' — Rainbow Robotics, Korea's Humanoid Pioneer [K-Humanoid Wars, Part 2]](https://cfnimage.commutil.kr/phpwas/restmb_setimgmake.php?pp=006&w=284&h=214&m=5&simg=2026022413501808272141825007d12411124362.jpg&nmt=18)

![Tesla's Humanoid Rival Has Arrived — Boston Dynamics Eyes $70 Billion Valuation [K-Humanoid Wars, Part 1]](https://cfnimage.commutil.kr/phpwas/restmb_setimgmake.php?pp=006&w=284&h=214&m=5&simg=2026022010243207659141825007d12411124362.jpg&nmt=18)

![Samsung's 'Last Chance': Lee Jae-yong Pushes HBM4 as Make-or-Break Moment [KFT Topic]](https://cfnimage.commutil.kr/phpwas/restmb_setimgmake.php?pp=006&w=284&h=214&m=5&simg=2026012623242806011141825007d122461258.jpg&nmt=18)

![Tesla's Humanoid Rival Has Arrived — Boston Dynamics Eyes $70 Billion Valuation [K-Humanoid Wars, Part 1]](https://cfnimage.commutil.kr/phpwas/restmb_setimgmake.php?pp=006&w=110&h=79&m=5&simg=2026022010243207659141825007d12411124362.jpg&nmt=18)

!['Samsung's Bet on the Future' — Rainbow Robotics, Korea's Humanoid Pioneer [K-Humanoid Wars, Part 2]](https://cfnimage.commutil.kr/phpwas/restmb_setimgmake.php?pp=006&w=110&h=79&m=5&simg=2026022413501808272141825007d12411124362.jpg&nmt=18)

!['From Heavy Industry to Humanoids' — Doosan Robotics Charts a New Future in Physical AI [K-Humanoid Wars, Part 3]](https://cfnimage.commutil.kr/phpwas/restmb_setimgmake.php?pp=006&w=110&h=79&m=5&simg=2026030310061306979141825007d12411124362.jpg&nmt=18)